In recent years, the use of small powder coating ovens has surged in popularity among hobbyists and small business owners alike, driven by the growing demand for high-quality finishes in various sectors, from automotive to furniture restoration. According to a report by the Coating Industry Research Institute, the powder coating market is projected to reach approximately $14 billion by 2027, highlighting the significant role small powder coating ovens play in fulfilling this demand. As more entrepreneurs choose to embrace powder coating for its durability and eco-friendliness, understanding the leading options on the market becomes essential.

Expert in the field, Dr. Emily Thompson, a noted authority on powder coating technologies, suggests, "The rise of small powder coating ovens makes it feasible for small businesses to achieve professional-grade results without the need for large-scale equipment." Her insights emphasize not only the accessibility but also the efficiency that these compact systems offer. With numerous models available, it is critical to evaluate their capabilities to determine which best suits diverse applications. This article explores the top 10 small powder coating ovens, providing insights into their features, benefits, and potential applications to aid consumers in making informed choices.

Powder coating has emerged as a popular finishing technique for both home projects and small businesses due to its durability and aesthetic appeal. This process involves applying a dry powder to the surface of an object, which is then cured under heat to create a tough, protective layer. The benefits of powder coating are significant; it provides a uniform finish, is environmentally friendly with low volatile organic compounds (VOCs), and offers a wide range of colors and textures. For small businesses, powder coating can enhance product quality and customer satisfaction while reducing the frequency of rework caused by chipping or fading finishes.

When considering powder coating for home use or for a small business, there are a few tips to keep in mind. First, always ensure that your workspace is well-ventilated and free of dust to avoid contamination during the coating process. Second, invest in quality powder coating equipment that suits your specific needs, which will ultimately save time and ensure a professional finish. Lastly, practice proper safety measures, such as wearing gloves and masks, to protect against any harmful particles or fumes produced during the curing phase.

Another essential tip is to prepare the surfaces properly before applying the powder coat. This includes cleaning, degreasing, and, if necessary, sandblasting to ensure optimal adhesion. Taking the time to prepare will not only yield a more durable finish but also enhance the overall appearance of the coated items. Embracing powder coating can greatly elevate the quality and longevity of your projects, whether at home or in a small business setting.

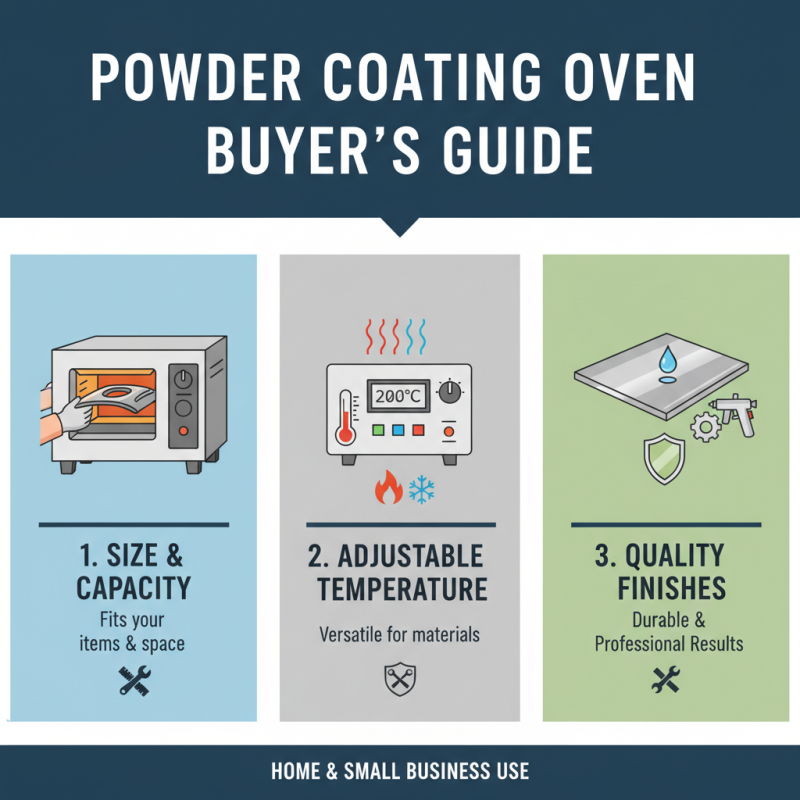

When selecting a small powder coating oven for home or small business use, several key features should be taken into account to ensure optimal performance and efficiency. First, consider the size and capacity of the oven. It should accommodate the size of the items you intend to coat while also fitting within your available workspace. Additionally, look for adjustable temperature settings; this allows you to achieve the specific heat required for various coatings, ensuring high-quality and durable finishes.

Another essential feature is the oven's heating method. Convection heating is commonly used, as it promotes even heat distribution, preventing any hot spots that could adversely affect the coating process. Pay attention to the insulation quality as well, as a well-insulated oven will maintain consistent temperatures and reduce energy consumption, leading to cost savings in the long run.

**Tips:** When using a powder coating oven, remember to preheat the items before coating to enhance adhesion and finish quality. Additionally, always invest in a reliable thermometer or digital temperature gauge to monitor the internal oven temperature accurately. This can help prevent overbaking or underbaking, which can compromise your project results.

When selecting a powder coating oven for home or small business use, it's essential to consider versatility, capacity, and energy efficiency. The right oven can significantly enhance your powder coating projects, ensuring a professional finish on various materials. Whether you're a hobbyist or running a small enterprise, choosing an oven that meets your specific needs can streamline your workflow and improve the quality of your work.

**Tips:** Always look for ovens with adjustable temperature settings and even heat distribution. This feature is crucial for achieving optimal curing results and avoiding uneven finishes. Additionally, consider the size of the oven relative to the items you plan to coat. A compact oven may be suitable for smaller projects, but larger items will require a bigger space.

Another aspect to keep in mind is the user interface and ease of use. Many modern powder coating ovens offer digital controls and timers, which can simplify the process for beginners and enhance precision for seasoned users. Make sure to read the specifications carefully and check for any additional features that could aid in your projects, such as built-in safety mechanisms or energy-saving modes.

| Model | Temperature Range (°F) | Chamber Size (inches) | Power (kW) | Weight (lbs) | Price (USD) |

|---|---|---|---|---|---|

| Model A | 200 - 400 | 24 x 24 x 36 | 3.0 | 150 | $1,200 |

| Model B | 250 - 450 | 32 x 32 x 36 | 3.5 | 180 | $1,500 |

| Model C | 300 - 500 | 30 x 30 x 24 | 4.0 | 210 | $1,800 |

| Model D | 225 - 475 | 28 x 28 x 30 | 3.2 | 160 | $1,400 |

| Model E | 200 - 450 | 36 x 36 x 48 | 4.5 | 220 | $2,200 |

| Model F | 250 - 400 | 24 x 24 x 36 | 3.1 | 140 | $1,000 |

| Model G | 280 - 500 | 30 x 30 x 36 | 4.2 | 200 | $1,750 |

| Model H | 240 - 480 | 32 x 32 x 36 | 3.8 | 190 | $1,600 |

| Model I | 260 - 450 | 28 x 28 x 28 | 3.6 | 170 | $1,300 |

| Model J | 230 - 480 | 36 x 36 x 30 | 4.0 | 210 | $1,900 |

When selecting a small powder coating oven for home or small business use, performance and pricing are two critical factors to consider. The efficiency of these ovens often relates to their heating capabilities, temperature uniformity, and build quality. Ovens that reach higher temperatures quickly and maintain consistent heat distribution are essential for achieving a strong, durable finish on coated items. Analyzing the energy consumption of each model can also provide insight into long-term operating costs, allowing users to make an informed decision based on both initial investment and ongoing expenses.

Pricing varies significantly across different models, reflecting differences in features and performance. Affordable options might have basic functionality with minimal temperature control, while higher-priced ovens may incorporate advanced features such as programmable settings or enhanced insulation. A comparative analysis enables potential buyers to weigh these aspects carefully, ensuring that they choose an oven that not only fits their budget but also meets their specific coating needs effectively. Balancing price against the capabilities and efficiency of the oven is vital for making a well-rounded choice that promotes successful powder coating results in a home or small business setting.

When using powder coating ovens at home or in small businesses, safety and effectiveness are paramount. It is essential to ensure proper ventilation, as powder coating involves the use of fine particles that can pose health risks when inhaled. According to the Occupational Safety and Health Administration (OSHA), maintaining good air quality in the workspace can significantly reduce the risk of respiratory ailments.

Implementing an effective dust collection system and using personal protective equipment (PPE), such as respirators and gloves, can provide necessary protection while working with these materials.

Additionally, the oven's temperature accuracy is crucial for achieving optimal results in powder coating. A study from the Powder Coating Institute highlights that maintaining a precise temperature range (typically between 350°F and 400°F) is critical for ensuring proper curing, which affects the durability and finish of the coated product. Home users should invest in thermometers or temperature probes to monitor oven performance, thus ensuring that the coating process is both safe and effective.

By prioritizing these safety tips, users can create a controlled environment that maximizes the benefits of powder coating while minimizing hazards.

Hein Minnie

Cell nr: +27 (0) 82 564 6501

Email: sale@thecirclemachine.com

Hein Minnie Jnr

Cell nr: +27 (0) 84 284 7234

Email: sale@thecirclemachine.com

Address:

10 Apsey Street,

Heidelberg,

Gauteng,

1441

Bendet Engineering Services (PTY) LTD was established in 1987. Our team of engineers and draughtsman are ready to deliver a complete turnkey solution, from the design phase to commissioning. A dedicated team that consists of electrical, mechanical and industrial engineers, we are able to offer a comprehensive service to our clients.