In the world of automotive refinishing, a "standard paint booth" serves as an essential tool. Experts emphasize its importance for achieving high-quality finishes. John M. Reynolds, a leading authority in spray booth technology, once stated, "A proper paint booth is vital for any successful painting operation."

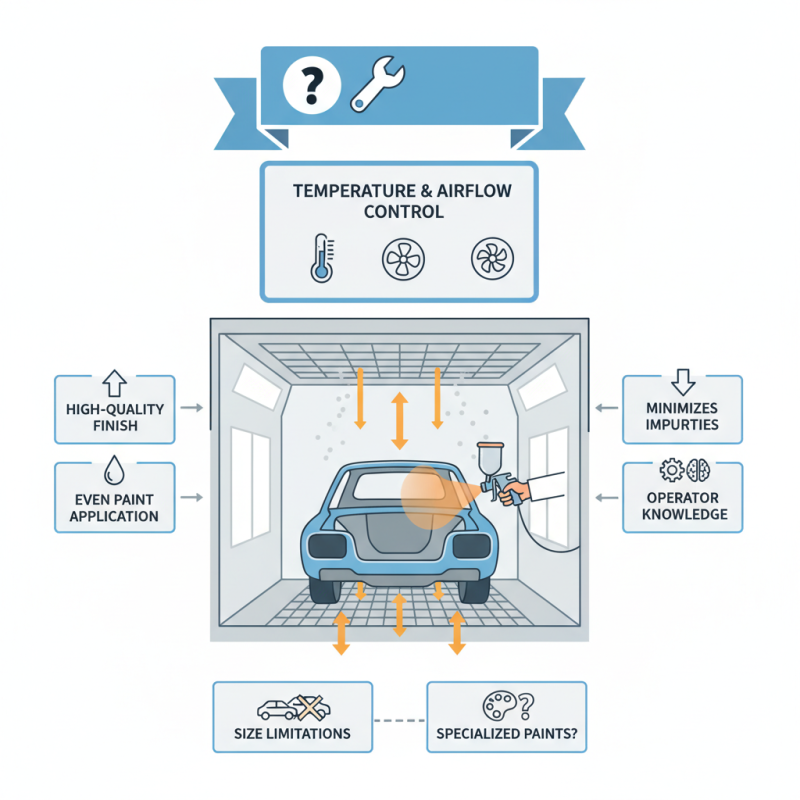

These booths are designed to control various factors, like temperature and airflow. This control minimizes impurities and helps achieve an even application of paint. In this environment, paint particles can settle uniformly without contamination. However, even the best-standard paint booths have limitations. For instance, not all booths can accommodate larger vehicles or specialized paints.

Efficiency in a standard paint booth does not come automatically. Operators must know the booth's specifics. They need to understand the different settings to maximize its potential. Attention to detail is crucial, as even minor oversights can lead to uneven finishes or defects. Reflecting on these aspects can enhance the effectiveness of any paint job and the longevity of the booth itself.

A standard paint booth is a controlled workspace designed for painting vehicles and equipment. These booths prevent harmful dust and debris from contaminating the paint. A typical booth features ventilation systems that filter the air, ensuring a clean environment for painting. This helps achieve a smoother finish and prevents imperfections.

When using a paint booth, safety is crucial. Workers should wear appropriate personal protective equipment. This includes masks and gloves to avoid inhaling fumes. Proper ventilation can make a huge difference. If the air isn’t properly filtered, the paint won’t adhere well, leading to flaws.

Tips for an effective paint booth: always check the booth’s lights before starting. Poor lighting can hide defects. Clean the surface of the object you're painting thoroughly. Any dirt or grease can ruin the finish. Regular maintenance of the booth's equipment is essential. Dirty filters can block airflow, leading to uneven paint application.

A standard paint booth is essential for efficient paint application. It includes several key components that ensure quality results. The air intake system pulls in fresh air, providing a clean environment. Filters remove dust and debris, preventing contamination of the paint. According to industry reports, a well-maintained booth can increase paint adhesion by up to 30%.

Adequate ventilation is crucial. Exhaust fans help maintain airflow, removing excess fumes and ensuring safety. These fans can often operate at varying speeds, offering flexibility based on the project size. Some facilities report a decrease in VOC (volatile organic compound) levels by up to 50% when using the right ventilation systems. However, not all booths achieve optimal performance due to design flaws or improper maintenance.

Another critical component is the lighting system. Proper lighting helps technicians see imperfections in the paint job. Bright, uniform light can highlight areas needing touch-ups. Many users overlook the significance of lighting. Inadequate lighting may result in missed flaws, leading to dissatisfaction. Regular assessments of each component are necessary. This can prevent costly rework and ensure consistent paint quality.

A standard paint booth operates on a straightforward mechanism that ensures efficient and safe painting processes. The booth is typically equipped with a ventilation system that maintains air quality. This system filters out hazardous particles and solvents, creating a safe environment for workers. Reports indicate that using a proper paint booth can reduce overspray by up to 90%. This reduction directly impacts paint waste and cost efficiency.

The working mechanism involves controlling airflow and temperature. Proper airflow helps remove volatile organic compounds (VOCs) from the booth. A well-regulated temperature ensures optimal paint curing times. For instance, studies show that ambient temperature can affect curing times by 20% or more. If the temperature fluctuates too much, it may lead to defects in the paint finish.

Moreover, paint booths can pose challenges. Regular maintenance is crucial to ensure filters work effectively. Neglected booths may decrease overall efficiency. A 2022 report noted that up to 30% of paint booths fail inspections due to poor maintenance. This statistic highlights the importance of diligence in upkeep to maintain high standards in painting applications.

| Dimension | Description |

|---|---|

| Size | Typically ranges from 10x10 feet to 14x40 feet depending on application needs. |

| Airflow System | Designed to provide a controlled airflow to facilitate even application of paint. |

| Filtration | Incorporates filters that reduce dust and contaminants in the air, ensuring a cleaner finish. |

| Lighting | Equipped with bright, shadow-free lighting that aids in accurate color matching and inspection. |

| Temperature Control | Maintains optimal temperature ranges to assist in paint curing and adhesion. |

| Safety Features | Includes fire suppression systems and explosion-proof electrical equipment to ensure safety. |

| Applications | Used in automotive refinishing, industrial coating, and furniture finishing among others. |

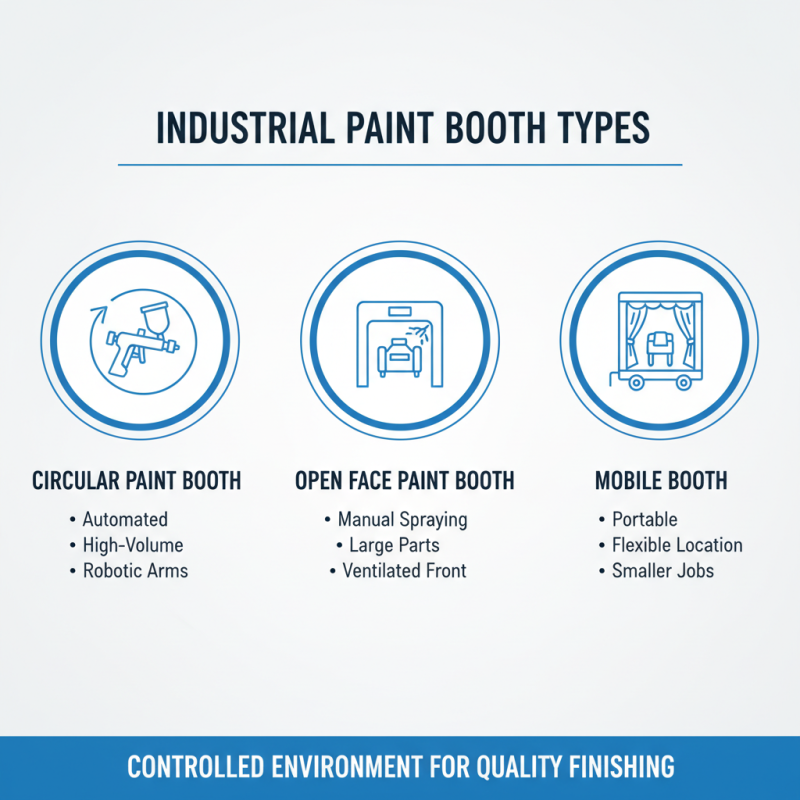

Paint booths are essential in many industries, providing controlled environments for painting and finishing products. There are several types of paint booths available, each designed for specific needs. The most common types are圭循环式涂装间,开放式涂装间和移动式涂装间。

Recirculating paint booths filter and reuse air, making them efficient and environmentally friendly. They are popular in large operations due to their ability to maintain air quality. Open paint booths allow for fresh air inflow, which can be beneficial for smaller projects. However, they can be less efficient and might require more frequent cleaning. Mobile paint booths are versatile and allow for on-site applications. They offer flexibility but may lack advanced filtration systems.

Each type has its advantages and drawbacks. Users often find themselves faced with choices that impact efficiency and workspace. There might be issues like overspray and paint waste. Choosing the right booth requires careful consideration of these factors. An informed decision can lead to better results, but it often involves balancing efficiency with cost.

In paint booth operations, safety measures are crucial. Proper ventilation is one of the main concerns. This helps to manage toxic fumes and paint overspray. High-quality filters play a vital role in maintaining air quality. Workers need to replace these filters regularly. This can be a tedious task but is necessary for safety.

Personal protective equipment (PPE) is essential in these environments. Wearing respirators can protect against harmful inhalation. Gloves and goggles also shield skin and eyes from spills. It is common to neglect PPE in busy settings. Many workers think short exposure is safe, but this is a misconception that can lead to serious health issues.

Regular training is another safety measure that should not be overlooked. Staff should understand how to use equipment properly. They also need to know emergency procedures like dealing with chemical spills. Failing to conduct these training sessions can lead to confusion in critical moments. Paint booths require constant vigilance and a culture of safety for all involved.

Hein Minnie

Cell nr: +27 (0) 82 564 6501

Email: sale@thecirclemachine.com

Hein Minnie Jnr

Cell nr: +27 (0) 84 284 7234

Email: sale@thecirclemachine.com

Address:

10 Apsey Street,

Heidelberg,

Gauteng,

1441

Bendet Engineering Services (PTY) LTD was established in 1987. Our team of engineers and draughtsman are ready to deliver a complete turnkey solution, from the design phase to commissioning. A dedicated team that consists of electrical, mechanical and industrial engineers, we are able to offer a comprehensive service to our clients.