In the fast-paced world of manufacturing and logistics, optimizing overhead conveyor systems has become a crucial element in enhancing operational efficiency and ensuring workplace safety. According to industry expert John Smith, a leading authority in material handling systems, "The key to maximizing productivity lies in the meticulous design and maintenance of overhead conveyors." These systems, which transport materials above the ground, not only save valuable floor space but also minimize the risk of workplace accidents by reducing congestion at ground level.

To achieve optimal performance, organizations must focus on several key factors, including system layout, load capacity, and maintenance protocols. By strategically designing overhead conveyor systems tailored to specific operational needs, manufacturers can streamline processes, reduce downtime, and increase throughput. Additionally, implementing regular maintenance routines helps to ensure safety and reliability, further enhancing the overall effectiveness of these systems. As companies continue to seek innovative solutions in the competitive industrial landscape, optimizing overhead conveyors will remain a pivotal focus for enhancing efficiency and maintaining high safety standards.

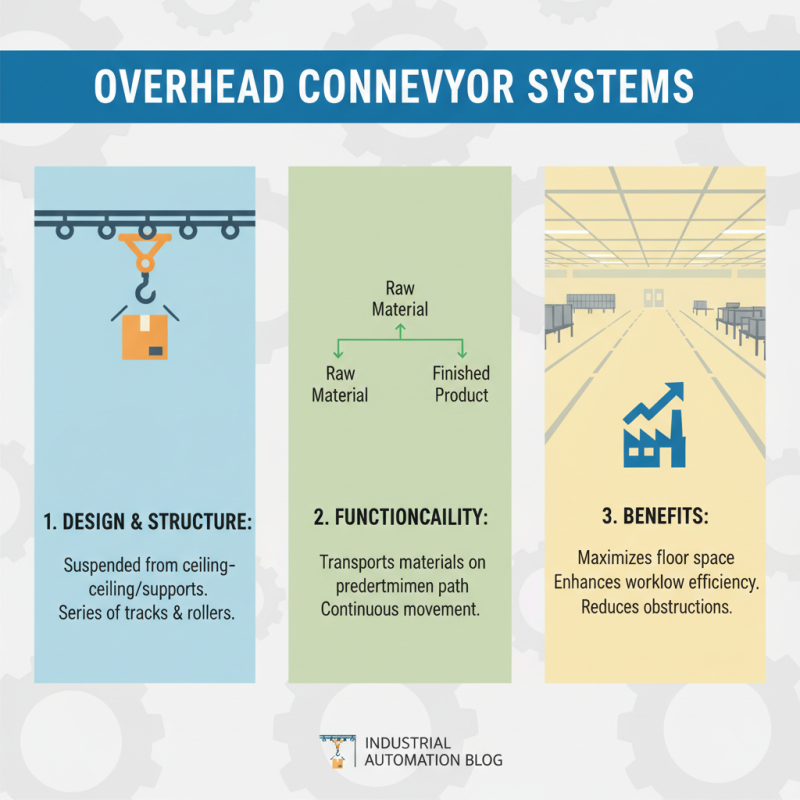

Overhead conveyor systems are an essential component in many manufacturing and distribution environments, facilitating the movement of materials and products with minimal floor space usage. Understanding the basics of these systems begins with recognizing their design and functionality. Typically suspended from ceilings or support structures, these conveyors utilize a series of tracks and rollers that allow items to be transported along a predetermined pathway. This vertical layout not only saves floor space but also enhances workflow efficiency by enabling continuous movement while keeping the production area clear of obstructions.

The versatility of overhead conveyor systems is exemplified by their various configurations, including chain-driven, belt-driven, and wire-rope systems. Each type is suited for specific applications based on the materials being transported and the desired speed of movement. Implementing these conveyors can significantly streamline operations in warehouses and factories, leading to reduced labor costs and increased safety. Proper understanding of system capacity, load limits, and maintenance requirements is crucial for optimizing performance, ensuring that the conveyor operates smoothly and safely while meeting the demands of the production line.

Overhead conveyor systems are crucial components in various industrial operations, significantly impacting both efficiency and safety. A recent industry report indicates that optimizing these systems can lead to a 20% increase in production speed while reducing labor costs by up to 30%. Key factors affecting the efficiency of these systems include the design of the conveyor layout, the speed of the conveyor belts, and the weight capacity of the system. Properly designing the layout to minimize the distance goods must travel can substantially enhance operational throughput. Additionally, maintaining an optimal belt speed ensures that the system operates smoothly without causing bottlenecks.

Safety in overhead conveyor systems hinges on factors such as system maintenance, operator training, and the incorporation of safety devices. A study from a leading manufacturing safety organization found that regular maintenance can reduce accident rates by as much as 50%. Operator training programs that emphasize safety protocols significantly lower the likelihood of human error, which is a leading cause of workplace accidents involving conveyor systems. Furthermore, integrating advanced safety technologies, such as automatic shut-off switches and improved visibility features, plays a critical role in mitigating risks associated with overhead conveyors, ensuring a safer working environment for all employees.

Optimizing overhead conveyor systems begins with a keen focus on system design and layout. According to a report from the Material Handling Industry of America, well-designed conveyor systems can enhance productivity by up to 30% while simultaneously reducing safety incidents by 25%. The key elements to consider include the trajectory of the conveyor, the materials being transported, and the spatial arrangement of workstations.

A well-planned layout minimizes bottlenecks and promotes a smooth flow of operations, fostering an ergonomic workspace that encourages employee well-being.

Tips: When designing your overhead conveyor system, start by mapping out the workflow of materials and personnel. Use simulation tools to visualize how your layout will impact efficiency and safety. Additionally, consider integrating adjustable conveyor heights to cater to different operational needs, making the workplace adaptable for various tasks and reducing strain on employees.

Alongside layout considerations, the integration of technology can play a vital role in optimizing overhead conveyor systems. Utilizing sensors and automation can help monitor system performance in real time, enabling swift adjustments to maintain efficiency. According to industry experts, automation can reduce operational costs by up to 20%. Ensuring that all safety measures, such as emergency stops and proper training, are in place adds another layer of protection, fostering a culture of safety while improving overall system reliability.

Tips: Regular maintenance checks and employee training on the latest safety protocols are crucial for sustaining an efficient overhead conveyor system. Implement a feedback loop where workers can report any concerns, facilitating continuous improvement and adapting the system to meet evolving operational challenges.

Regular maintenance and inspection procedures are crucial for optimizing overhead conveyor systems, significantly enhancing both efficiency and safety in various industrial settings. According to a report by the Conveyor Equipment Manufacturers Association (CEMA), preventive maintenance can reduce unexpected machinery failures by up to 30%. Implementing a routine inspection schedule that includes checking for wear and tear, proper alignment, and lubrication can help identify potential issues before they escalate into costly downtime.

Moreover, safety is paramount in the operation of overhead conveyors. A study from the Occupational Safety and Health Administration (OSHA) revealed that regular maintenance not only extends the life of the equipment but also minimizes the risk of workplace accidents. For instance, conducting monthly inspections to assess the integrity of the support structures and conveyor belts can prevent incidents related to equipment malfunctions. These proactive measures not only foster a safer work environment but also contribute to a more efficient production flow, as systems that are well-maintained tend to operate at optimal speeds and capacities.

Effective training and safety protocols for operators and personnel are crucial in optimizing overhead conveyor systems. A well-structured training program should focus on both the technical aspects of operating the conveyor and the safety measures necessary to protect personnel. Operators must be familiar with the components of the system, such as the drive unit, pulleys, and safety stops, to ensure that they can effectively manage operations while minimizing risks. Regular training sessions, including hands-on practice and simulations, can enhance their skills and reinforce safe practices.

In addition to operator training, implementing thorough safety protocols is essential for maintaining a safe working environment. This includes conducting risk assessments to identify potential hazards associated with the conveyor system and establishing clear guidelines for safe operation. Personnel should be trained on emergency procedures, proper use of personal protective equipment (PPE), and the importance of communicating effectively when working near the conveyor. Furthermore, frequent safety audits and feedback loops can help identify areas for improvement, ensuring that safety remains a priority in the operational workflow. By prioritizing training and safety protocols, organizations can significantly enhance the efficiency and safety of their overhead conveyor systems.

Hein Minnie

Cell nr: +27 (0) 82 564 6501

Email: sale@thecirclemachine.com

Hein Minnie Jnr

Cell nr: +27 (0) 84 284 7234

Email: sale@thecirclemachine.com

Address:

10 Apsey Street,

Heidelberg,

Gauteng,

1441

Bendet Engineering Services (PTY) LTD was established in 1987. Our team of engineers and draughtsman are ready to deliver a complete turnkey solution, from the design phase to commissioning. A dedicated team that consists of electrical, mechanical and industrial engineers, we are able to offer a comprehensive service to our clients.