The downdraft paint booth is a critical component in the automotive and manufacturing industries. According to a report by IBISWorld, the global paint booth market was valued at over $1.5 billion in 2022 and is projected to grow steadily. This growth reflects the increasing demand for high-quality finishes in various sectors. A downdraft paint booth ensures that paint application is efficient and clean, enhancing both productivity and quality.

In these booths, air flows from the top down, creating a controlled environment. This design helps in removing overspray and particulates from the air, which is vital for achieving flawless finishes. However, there are challenges to consider. The initial setup cost can be high, and maintenance may require trained personnel. Moreover, users must reflect on the energy consumption these systems demand.

The downdraft paint booth also plays a vital role in safety. By keeping harmful fumes and particles contained, it protects workers and the environment. Yet, the effectiveness of a downdraft paint booth relies on proper ventilation and filtration systems. Failure to maintain these components can lead to inadequate performance and safety hazards.

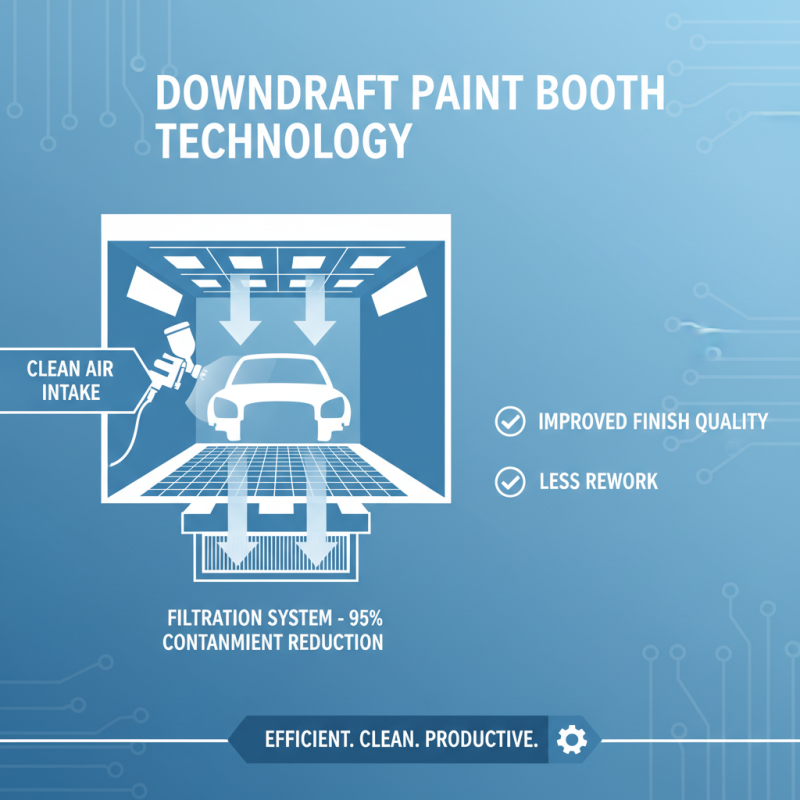

A downdraft paint booth is a specialized workspace. Its primary purpose is to control air quality while painting. This ensures a clean, efficient environment for the application of paint. According to industry data, these booths can reduce airborne contaminants by up to 95%. This significant reduction in particulates boosts the quality of the finish and reduces rework.

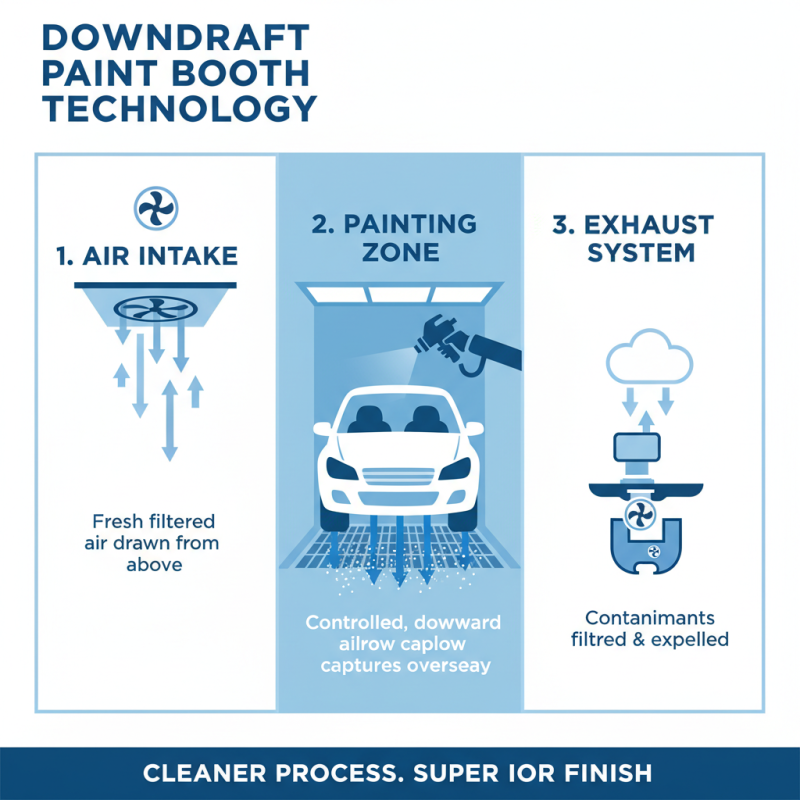

The operation of a downdraft paint booth involves drawing air from above. Clean air flows downwards, effectively capturing dust and particles. This method creates a safer workspace for operators. Additionally, it supports better adhesion of paint to surfaces. Some studies indicate that using a downdraft booth can improve paint application efficiency by 25%. However, maintaining these booths can be complex and costly. Regular maintenance is crucial to keep air quality high.

While downdraft booths offer many benefits, they also come with challenges. For instance, installation requires careful planning and space consideration. Not every facility can accommodate these booths. Furthermore, energy consumption is a concern. Running these systems efficiently is essential for sustainability. In some cases, businesses may struggle with the upfront investment and ongoing costs. Balancing these factors is crucial for effective operations in the painting industry.

A downdraft paint booth is an essential space for automotive painting and industrial coating. Its unique design ensures that the paint is applied evenly and without contaminants. One of the key components is the downdraft system. This system pulls air from above, directing it downward. It captures overspray and keeps the paint job clean.

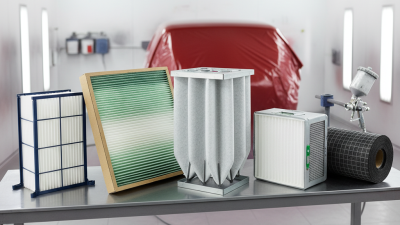

Another crucial element is the filtration system. Filters remove dust and particles from the air before it enters the booth. This process is vital for achieving a smooth finish on surfaces. Some booths have multiple layers of filtration, ensuring high air quality. This can sometimes mean increased maintenance challenges. Filters must be replaced regularly, which can be an overlooked task.

Lighting in a downdraft booth is also significant. Proper lighting helps in identifying imperfections during the painting process. LED lights often offer the best illumination. However, these need to be positioned correctly to avoid shadows or glare. Some painters struggle to adjust to lighting, affecting their work quality. While downdraft booths are highly efficient, they also require diligent upkeep and attention to detail for optimal performance.

A downdraft paint booth is designed to provide an efficient painting environment. It uses a unique airflow system. Air is drawn downwards from above the painting area. This method ensures that overspray and particulates are removed quickly. The result is a cleaner painting process and improved surface finish.

The operational mechanism relies on fans and filters. High-velocity fans create a steady airflow. The air enters from the ceiling and exits through the floor. As paint is applied, the excess particles are captured. However, this system can have its challenges. Filters need regular maintenance; neglect affects performance. Uneven airflow can lead to inconsistent finishes.

Temperature control is also crucial. Too cold or hot can impact paint adhesion. Painters need to monitor conditions closely. It becomes an ongoing learning process. Mistakes are part of mastering the art of using a downdraft paint booth. Experimentation reveals the nuances of this technology.

A downdraft paint booth is a specialized enclosure designed for automotive painting and industrial applications. It utilizes a unique airflow system that pulls air downwards, helping to remove overspray and contaminants. This feature aids in creating a clean environment, essential for achieving high-quality finishes.

One of the most notable benefits is improved air quality. The downward airflow minimizes particles from floating back onto painted surfaces. This leads to fewer imperfections on the final product. Furthermore, it reduces the risks of health hazards associated with inhaling fumes. The controlled environment can enhance the longevity of paint jobs.

Efficiency is another advantage. Downdraft booths can speed up the drying process, thanks to consistent airflow. However, they require careful maintenance. Dust and debris can accumulate in filters and ducts, impacting performance. Regular cleaning of the system is essential to avoid these pitfalls. A commitment to upkeep can ensure better results in the long run.

Maintaining a downdraft paint booth is crucial for optimal performance. Regular inspections are necessary. Filters should be checked frequently. They can become clogged, affecting airflow. A clean booth promotes better paint application. Ensure the exhaust system is functioning well. Poor ventilation can lead to hazardous fumes accumulating.

Safety considerations are also important. Proper personal protective equipment (PPE) must be worn. This includes gloves, goggles, and respirators. Employees should be trained in safe operating procedures. Fire extinguishers should be accessible and regularly checked. A first-aid kit must be readily available.

Despite all precautions, issues can still arise. Sometimes, even trained personnel may overlook simple tasks. Missing a filter change can be costly. It’s vital to foster a culture of accountability. Each worker plays a part in maintaining safety and efficiency. Regular training refreshers can help keep everyone vigilant. Encouraging open discussions about safety concerns can lead to improvements.

| Aspect | Details |

|---|---|

| Function | Creates a controlled airflow that directs overspray and airborne particles downwards, preventing contamination. |

| Airflow Type | Downdraft - air is pulled from above and exhausted downwards, often through a grating in the floor. |

| Key Components | Ventilation system, filters, heating elements, and lighting. |

| Maintenance Frequency | Regular checks every month; deep cleaning and filter replacement every six months. |

| Safety Measures | Proper personal protective equipment (PPE), adequate ventilation, and regular safety training for operators. |

| Common Issues | Clogged filters, fan malfunctions, and inadequate air flow can impact performance. |

| Usage Industries | Automotive, aerospace, furniture, and manufacturing sectors. |

Hein Minnie

Cell nr: +27 (0) 82 564 6501

Email: sale@thecirclemachine.com

Hein Minnie Jnr

Cell nr: +27 (0) 84 284 7234

Email: sale@thecirclemachine.com

Address:

10 Apsey Street,

Heidelberg,

Gauteng,

1441

Bendet Engineering Services (PTY) LTD was established in 1987. Our team of engineers and draughtsman are ready to deliver a complete turnkey solution, from the design phase to commissioning. A dedicated team that consists of electrical, mechanical and industrial engineers, we are able to offer a comprehensive service to our clients.