In today's fast-paced industrial landscape, conveyor systems are vital for efficiency and productivity. According to a report by MarketsandMarkets, the global conveyor systems market is expected to reach $10.5 billion by 2025, growing at a CAGR of 4.5%. This growth underscores their importance in manufacturing, logistics, and warehousing.

Conveyor systems streamline operations and reduce manual labor. With automation on the rise, these systems can transport materials quickly and safely over long distances. For instance, automated conveyor systems can move products in factories, ensuring timely distribution. However, not all installations go as planned. Poor system design can lead to inefficiencies and increased downtime.

Investing in conveyor technology can reduce operational costs. However, companies must continually evaluate their systems. Are they achieving maximum efficiency? Regular audits can reveal gaps in performance. In an age of rapid technological advancement, balancing innovation with practical operation is a constant challenge.

Conveyor systems play a crucial role in modern manufacturing efficiency. These systems streamline processes, reduce manual labor, and increase throughput. According to a report by the Conveyor Equipment Manufacturers Association, industrial conveyor systems can boost productivity by up to 50%. This significant increase often translates directly into cost savings for businesses.

One key advantage of conveyor systems is their ability to handle various materials. They can transport heavy loads over long distances with minimal energy consumption. This efficiency is vital in industries such as food processing, automotive, and electronics. However, improper maintenance can lead to frequent breakdowns. Regular inspection schedules are essential to mitigate unexpected downtimes.

Tip: Develop a routine inspection checklist for conveyor systems. Ensure moving parts are lubricated and that belts are aligned correctly.

Moreover, automation is transforming the role of conveyor systems. Smart sensors can monitor workflow and identify bottlenecks. While this innovation represents a leap forward, it can be challenging to integrate into existing setups. Companies should assess their systems before making upgrades.

Tip: Consider performing a technology audit to evaluate current system capabilities. This may reveal areas needing attention before investing in automation.

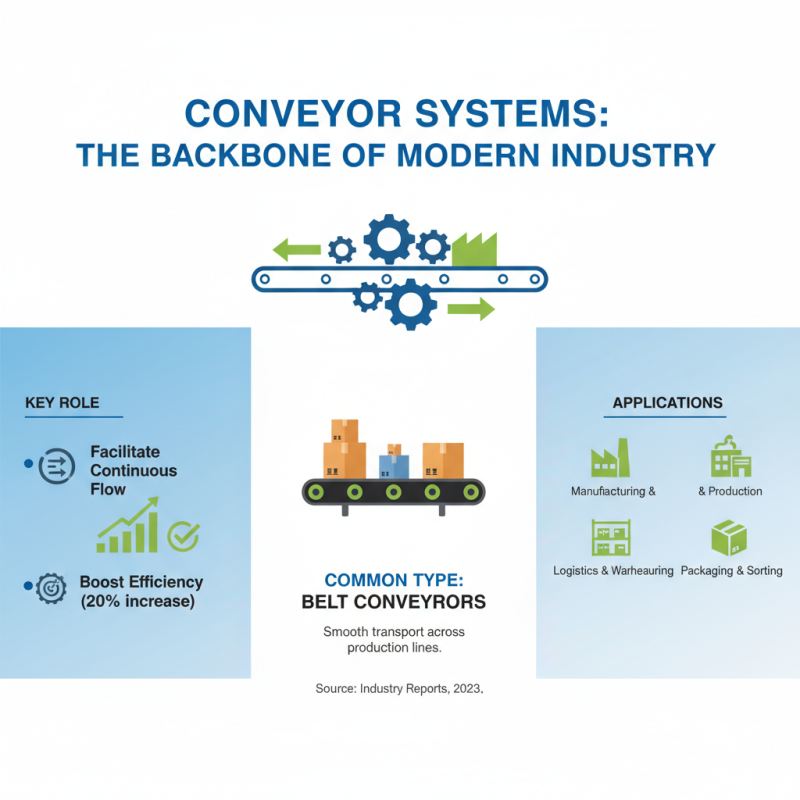

Conveyor systems play a key role in modern industries. Various types of conveyor systems cater to different needs and applications. For example, belt conveyors are common in manufacturing. They transport items smoothly across production lines, enabling continuous flow. In fact, industries report a 20% increase in efficiency when using these systems, according to recent studies.

Roller conveyors are another option. They are excellent for moving heavy packages. Warehouses often rely on these systems for sorting and distributing goods. In logistics, the integration of conveyor systems can reduce labor costs by up to 30%. However, companies sometimes overlook maintenance. Faulty systems lead to downtime and lost productivity.

Tips: Regular inspections can prevent potential issues. Ensure your system is compatible with your products. Training personnel on proper usage also enhances efficiency. A small investment in training can yield significant returns. With the right setup, conveyor systems enhance operational flow, fulfilling the demands of modern industries effectively.

Conveyor systems play a pivotal role in modern industries by streamlining operations. They help companies reduce labor costs significantly. Automated transport removes the need for manual handling of materials. This efficiency is crucial in high-demand sectors such as manufacturing and logistics.

Consider a factory floor. With conveyor belts in place, workers can focus on tasks that require skill. This shift minimizes repetitive strain injuries and maintains productivity. However, implementing a conveyor system requires an upfront investment. Some companies hesitate due to costs, which might not guarantee immediate payback.

Yet, many find that the long-term savings outweigh initial hesitations. Automated systems can run continuously, reducing downtime. A well-planned conveyor system can optimize workflow as well. Still, it often requires regular maintenance. Neglecting this can lead to unexpected breakdowns, affecting overall efficiency.

Conveyor systems are transforming workplace safety and ergonomics. They reduce the need for manual lifting, which causes many injuries. According to the Bureau of Labor Statistics, over 400,000 workers suffered from musculoskeletal disorders in 2021 due to manual handling. By implementing conveyor systems, industries can mitigate these risks significantly.

In addition to enhancing safety, these systems improve operational efficiency. A report from the National Institute for Occupational Safety and Health indicates that ergonomic interventions can lead to productivity increases of up to 30%. Conveyors enable smooth material flow, but they also create new challenges. Workers must be trained properly to operate these systems safely.

Furthermore, poorly designed systems can lead to ergonomic strain and safety hazards, which could be easily overlooked.

Proper maintenance of conveyor systems is crucial. Neglecting regular checks can lead to accidents and downtime. Many facilities still ignore ergonomic principles in their design. As the industry progresses, companies must remain vigilant.

Safety should never be an afterthought, nor should ergonomic considerations be secondary.

Conveyor systems are evolving rapidly. Advancements in technology are setting new standards in efficiency. Automation is becoming key. Smart conveyors now integrate sensors and AI. This allows real-time monitoring and adjustments. These systems can predict maintenance needs. They reduce downtime and enhance productivity.

Sustainability is also a focus. Eco-friendly materials and energy-efficient designs are on the rise. Companies are looking to minimize their carbon footprint. Streamlining processes is essential for growth. Yet, the challenge lies in balancing costs and benefits. Not all businesses can afford these upgrades.

Adaptability is crucial. Conveyor systems must meet diverse industry needs. Customization is becoming more important. Companies often struggle with this aspect. It’s not easy to find the right solutions. Future trends suggest a shift towards modular systems. These can be easily modified as demands change. This flexibility could shape the future of manufacturing.

| Feature | Description | Importance | Future Trends |

|---|---|---|---|

| Automation | Integration of robotics and AI to enhance efficiency. | Reduces labor costs and increases output. | Greater reliance on smart technologies for monitoring. |

| Energy Efficiency | Use of energy-efficient motors and materials. | Lower operational costs and sustainability. | Emergence of renewable energy sources in powering systems. |

| Modularity | Modular designs allow for easy scaling and customization. | Flexibility to adapt to changing industry needs. | Growth of adaptable systems that can be reconfigured easily. |

| Safety Features | Enhanced safety systems for worker protection. | Minimized risk of accidents and increased employee confidence. | Integration of IoT for real-time safety monitoring. |

| Predictive Maintenance | Use of sensors to predict equipment failures. | Minimizes downtime and maintenance costs. | Advancement in AI for improved predictive analytics. |

Hein Minnie

Cell nr: +27 (0) 82 564 6501

Email: sale@thecirclemachine.com

Hein Minnie Jnr

Cell nr: +27 (0) 84 284 7234

Email: sale@thecirclemachine.com

Address:

10 Apsey Street,

Heidelberg,

Gauteng,

1441

Bendet Engineering Services (PTY) LTD was established in 1987. Our team of engineers and draughtsman are ready to deliver a complete turnkey solution, from the design phase to commissioning. A dedicated team that consists of electrical, mechanical and industrial engineers, we are able to offer a comprehensive service to our clients.