Choosing the right curing oven for your business can be a daunting task. Industry expert James Hartley once stated, "A well-selected curing oven makes all the difference in product quality." This highlights the importance of this equipment in various sectors, from manufacturing to artisanal crafts.

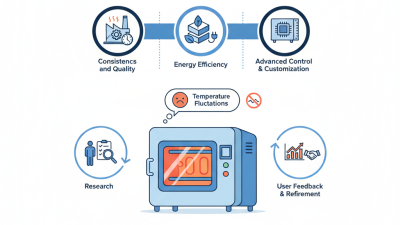

When selecting a curing oven, consider the specific requirements of your business. Different materials and techniques demand unique features. For instance, your chosen oven must maintain consistent temperatures. Uneven heat can lead to product inconsistencies. Look for options that provide excellent insulation and precise temperature control.

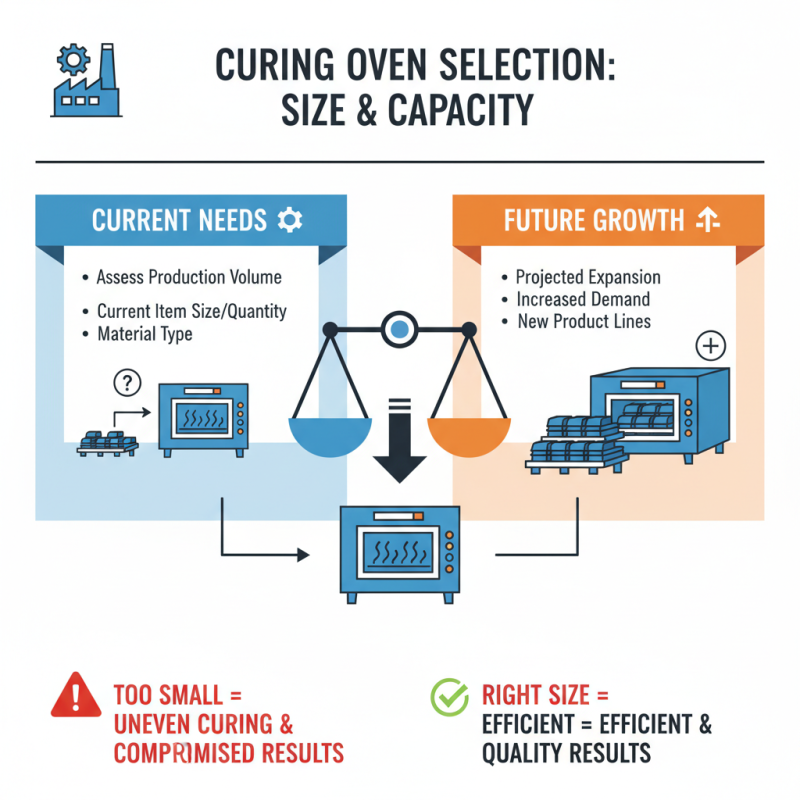

In addition, consider the oven’s size and capacity. Oversized ovens may waste energy, while undersized ones could limit production. Explore options tailored to your needs. A thoughtful choice can improve efficiency, save costs, and enhance product standards. Embracing this process with careful consideration may reveal aspects you hadn’t first anticipated. Choosing an ideal curing oven isn't just about the immediate gain. It’s an investment in your brand's future.

When selecting a curing oven, it's crucial to understand the different types available. Curing ovens come in various designs and functions. Each type serves unique purposes that cater to different industries. For example, some are built for high-temperature processes, while others focus on low-energy consumption. The choice often depends on your specific requirements.

Electric curing ovens are popular due to their ease of use. They provide consistent heat distribution. Gas-fired ovens may offer faster heating times, but they can be less energy-efficient. Infrared curing ovens are gaining popularity for their ability to heat objects quickly. They are ideal for small and intricate items. However, their upfront cost can be a concern for some businesses.

Reflecting on needs is essential. Do you prioritize speed, energy efficiency, or versatility? It’s easy to overlook the importance of space. Make sure the oven fits well into your workspace. A larger oven might seem beneficial, but it could lead to unnecessary energy waste. Consider also the maintenance aspects of your selection. It’s essential to choose an oven that you can maintain easily.

| Type of Curing Oven | Temperature Range (°F) | Typical Applications | Energy Efficiency | Recommended Industries |

|---|---|---|---|---|

| Convection Oven | 100 - 400 | Coatings, Paints | High | Manufacturing, Automotive |

| Infrared Curing Oven | 120 - 300 | Plastic Coatings, Adhesives | Medium | Textiles, Electronics |

| Batch Curing Oven | 150 - 500 | Large Parts, Industrial Applications | Moderate | Aerospace, Heavy Machinery |

| Continuous Curing Oven | 140 - 600 | High-volume Production, Continuous Processing | Very High | Automotive, Construction |

| Vacuum Curing Oven | 100 - 300 | Composite Materials, Resins | High | Aerospace, Advanced Manufacturing |

Choosing the right curing oven is not an easy task. There are several key factors to think about. Start with the size of the oven. Determine how much space you have. Consider your production volume too. An oven that’s too small can limit your output. But a large oven can waste energy and resources.

Temperature control is another important aspect. Opt for an oven that allows precise temperature adjustments. This flexibility is crucial for various curing processes. Note that different materials may require different curing temperatures. Also, check the heating method. Some ovens use convection, while others rely on infrared. Each has its advantages and drawbacks.

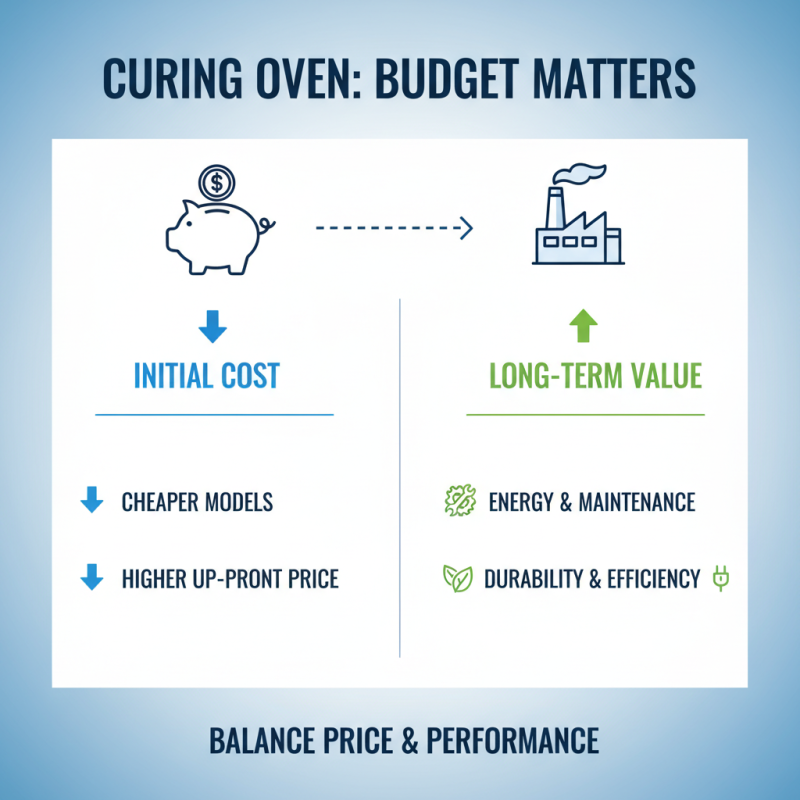

Energy efficiency matters in today’s market. An efficient oven saves money and reduces environmental impact. However, efficiency sometimes comes at a higher initial cost. Weigh your budget against potential long-term savings. It's worth considering the features that can help maintain consistent results. Curing can sometimes be tricky, so don’t rush your decision. Take your time to research thoroughly.

When selecting the right curing oven, size and capacity are key factors. Think about the volume of items you need to cure regularly. It’s important to assess what you currently produce and what you plan to grow into. If your business is expanding, consider future demands. Choosing too small an oven could mean constant overcrowding. This may lead to uneven curing and compromised results.

Another point to consider is the dimensions of your workspace. Ensure that the oven fits comfortably in your production area. A cramped environment can hinder workflow. It also increases the risk of accidents. It might be tempting to opt for a larger oven, but this can create problems too. Oversized ovens can waste energy and resources. They may also require more maintenance than necessary. Each choice has trade-offs. Evaluate your immediate needs against long-term goals carefully. Listen to what your production process tells you. Your oven should complement, not complicate, your operations.

When choosing a curing oven, budget plays a crucial role. Every business has financial limits, and selecting the right oven should align with those constraints. Analyze both initial costs and long-term savings. Often, cheaper models may require more energy or maintenance, which can add up over time. A more expensive oven might be cost-effective in the long run.

Consider the size and capacity of the oven as well. A smaller oven may save you money upfront, but could limit production. Evaluate your production needs carefully. Some businesses underestimate their requirements, leading to costly upgrades later on. Additionally, energy efficiency is significant. A well-designed oven saves energy, lowering operating costs. However, not all models have clear energy ratings. Researching this can lead to informed decisions.

Remember to think about the features you need. While advanced features can enhance efficiency, they often come at a higher price. Prioritize what is essential versus what is a luxury. Reflect on your business processes and where improvements can be made. Sometimes, it’s better to invest in quality rather than quantity. The right choices today impact your budget tomorrow.

When selecting a curing oven for your business, maintenance and support are crucial factors. A recent industry report shows that proper maintenance can extend the life of your equipment by up to 40%. This is significant when budgets are tight. Ignoring maintenance can lead to costly downtimes and repairs. It's important to choose an oven with easily accessible parts for quick repairs.

Support options are equally vital. Many businesses opt for ovens with robust customer service options. A study revealed that 65% of companies prefer suppliers that offer comprehensive training and troubleshooting. This support can prevent minor issues from escalating. Look for companies that provide warranties and service agreements. Simple things, like the availability of replacement parts, should not be overlooked. Equipment breakdowns can halt production.

Investing time in researching maintenance practices is essential. Many users report unclear maintenance instructions from manufacturers. This can lead to improper care and reduced oven efficiency. A solid choice should come with clear support resources, training personnel, and readily available documentation. Keeping your curing oven functioning effectively requires ongoing effort and thoughtful consideration.

Hein Minnie

Cell nr: +27 (0) 82 564 6501

Email: sale@thecirclemachine.com

Hein Minnie Jnr

Cell nr: +27 (0) 84 284 7234

Email: sale@thecirclemachine.com

Address:

10 Apsey Street,

Heidelberg,

Gauteng,

1441

Bendet Engineering Services (PTY) LTD was established in 1987. Our team of engineers and draughtsman are ready to deliver a complete turnkey solution, from the design phase to commissioning. A dedicated team that consists of electrical, mechanical and industrial engineers, we are able to offer a comprehensive service to our clients.