When embarking on your next project, selecting the right powder coating can make all the difference in achieving a durable and aesthetically pleasing finish. According to industry expert Dr. Samuel Greene, a leading authority in coatings technology, “The key to a successful application is understanding the specific requirements of your project and choosing a powder coating that meets those needs.” With numerous options available, it can be overwhelming for both professionals and DIY enthusiasts to navigate the sea of powders and finishes.

The world of powder coating offers an array of textures, colors, and functionalities that cater to diverse applications, from automotive parts to home furnishings. By taking the time to research and understand the various types of powder coatings, you can ensure that your final product not only looks great but also withstands the rigors of the environment it will face. In this guide, we will explore essential factors to consider when choosing the best powder coating for your next project, helping you to make an informed decision that enhances both value and performance.

Powder coating is a versatile finishing process that has gained popularity across various industries due to its durability and aesthetic appeal. Unlike traditional liquid paints, powder coating involves the application of a dry powder that is then cured under heat to form a hard, protective layer. According to a report by the Powder Coating Institute, the global powder coating market was valued at approximately $11 billion in 2020, and it is projected to grow significantly in the coming years, driven by increased demand in automotive, architectural, and appliance sectors.

The benefits of powder coating over conventional paint are substantial. For instance, powder coatings are known for their superior durability, which can significantly extend the lifespan of finished products. The American Coatings Association indicates that powder-coated surfaces are more resistant to chipping, scratching, and fading, providing a long-lasting finish that outperforms standard paints. Additionally, powder coating is an environmentally friendly option as it produces minimal volatile organic compounds (VOCs) during application, contributing to safer working conditions and reducing environmental impact.

Furthermore, the versatility of powder coating allows for a wide range of textures and finishes, enabling designers to achieve their desired aesthetic outcomes. With its ability to provide even coverage and a robust finish in many colors and styles, powder coating offers not just protective advantages, but also creative possibilities that cater to diverse project needs. This unique combination of durability, environmental benefits, and aesthetic flexibility makes powder coating an increasingly attractive option for various applications in the modern manufacturing landscape.

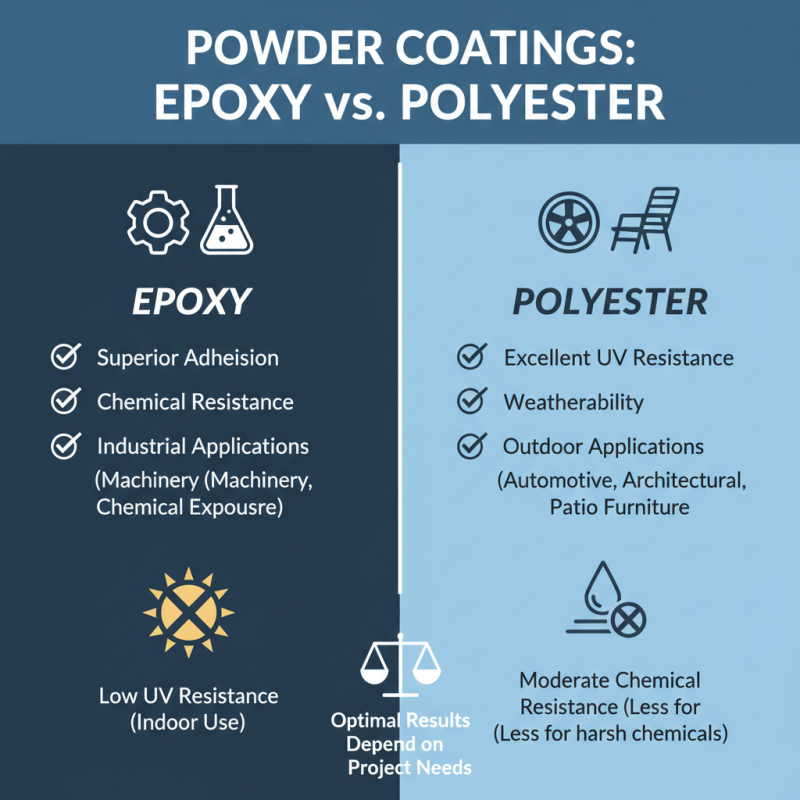

When selecting the ideal powder coating for your next project, there are several key factors to consider that can significantly impact both the application process and the final results. One primary aspect is the type of resin used in the powder coating, which can include polyester, epoxy, or hybrid formulations. According to the Powder Coating Institute, polyester powder coatings are well-suited for outdoor applications due to their excellent UV stability, making them a preferred choice in various industries. Conversely, epoxy coatings are praised for their superior adhesion and chemical resistance, ideal for indoor environments where durability is vital.

Another critical consideration is the desired finish and texture of the coating. The powder coating market has shown that finishes can range from matte to glossy, and the surface texture can vary from smooth to textured options like wrinkle or pebble finishes. The choice of finish not only influences the aesthetic appeal but also affects the coating's performance in specific environments. For instance, textured coatings can hide surface imperfections better than smooth finishes, making them suitable for industrial applications.

**Tips:** When choosing a powder coating, always assess the environmental conditions the finished product will face, such as exposure to chemicals, moisture, or weather. Additionally, it's advisable to review the manufacturer’s technical data sheets for information on cure times, application methods, and any recommended pre-treatment processes that enhance adhesion. Lastly, consulting industry reports can provide insights into emerging trends in powder coating technologies, helping you make an informed decision that aligns with your project requirements.

When selecting the best powder coating for a project, understanding the differences between epoxy and polyester coatings is crucial for achieving optimal results. Epoxy powder coatings are known for their exceptional adhesion and chemical resistance, making them suitable for harsh environments. They are often preferred for industrial applications, such as machinery parts or items exposed to chemicals, as they can withstand significant wear and tear. However, epoxy coatings tend to have lower UV resistance, which limits their use in outdoor applications where long-term exposure to sunlight can cause degradation.

On the other hand, polyester powder coatings offer excellent durability and UV stability, making them ideal for exterior applications. They retain their color and gloss over time, effectively resisting fading due to outdoor conditions. Polyester coatings are widely used for architectural elements, such as facades and outdoor furniture, where aesthetic appeal and longevity are essential. Additionally, they provide good weather resistance and mechanical properties, making them versatile for various applications. By considering these characteristics, individuals can make informed choices between epoxy and polyester coatings based on their specific project needs and environmental conditions.

When selecting the right powder coating for your project, evaluating color, finish, and texture is essential for achieving the desired aesthetic and functional qualities. Color selection is often the first consideration, as it can significantly influence the overall appearance of the finished product. Consider the environment in which the coated item will be placed, as well as any branding requirements. Additionally, explore the color range available, including standard and custom options, to find the perfect hue that aligns with your vision.

Beyond color, the finish of the powder coating plays a crucial role in both appearance and durability. Options typically range from glossy to matte finishes, each providing a distinct look and feel. Glossy finishes tend to enhance color vibrancy and reflectivity, making them suitable for high-impact visual projects, while matte finishes offer a more subdued and sophisticated look that can hide surface imperfections. Texture is another key aspect, with options such as smooth, textured, or wrinkled surfaces that can add depth and character. Selecting the appropriate texture not only contributes to aesthetics but also affects functionality by improving grip or masking fingerprints. By thoughtfully assessing these factors, you can ensure your powder coating choice not only meets practical needs but also elevates the visual impact of your project.

When selecting powder coating for your project, understanding industry standards and certifications is crucial to ensure quality and durability. The Powder Coating Institute (PCI) and other organizations set guidelines that help determine the performance characteristics of various coatings. Look for coatings that adhere to ASTM (American Society for Testing and Materials) standards, which evaluate properties such as adhesion, corrosion resistance, and impact strength. These certifications signify that the powder coating has been tested and meets specific performance criteria, providing assurance of its quality.

Hein Minnie

Cell nr: +27 (0) 82 564 6501

Email: sale@thecirclemachine.com

Hein Minnie Jnr

Cell nr: +27 (0) 84 284 7234

Email: sale@thecirclemachine.com

Address:

10 Apsey Street,

Heidelberg,

Gauteng,

1441

Bendet Engineering Services (PTY) LTD was established in 1987. Our team of engineers and draughtsman are ready to deliver a complete turnkey solution, from the design phase to commissioning. A dedicated team that consists of electrical, mechanical and industrial engineers, we are able to offer a comprehensive service to our clients.