In the world of automotive refinishing, choosing the right mobile paint booth can significantly impact your results. Expert John Smith, a leading figure in the mobile paint booth industry, emphasizes, "The right booth can transform your painting process." A mobile paint booth provides flexibility and efficiency, catering to various needs.

When selecting a mobile paint booth, consider size, setup time, and airflow features. Each element plays a critical role in achieving optimum results. A poorly chosen booth can lead to uneven finishes and wasted materials, highlighting the need for careful consideration. It’s not always easy to spot the right fit at first glance.

Moreover, think about your specific requirements. Are you working on large vehicles or smaller items? This decision will shape your search. Engaging with experts can help clarify doubts. However, personal experience and reflection are equally important in this journey. The perfect mobile paint booth is out there, waiting for you to discover it.

When selecting a mobile paint booth, several factors come into play. First, assess the size and space requirements. Ensure the booth can accommodate the largest items you plan to paint. Measure your workspace to avoid unexpected challenges. A booth that feels cramped can affect your work quality.

Next, consider airflow and ventilation. Proper airflow is crucial for safety and paint application. Look for booths designed with effective exhaust systems. A well-ventilated booth helps create a more comfortable working environment. You might find that some booths have insufficient ventilation. This can lead to poor finish and health risks from fumes.

Budget is another important aspect. Mobile paint booths vary significantly in cost. While it’s tempting to go with cheaper options, lower prices could result in subpar performance. Invest in a booth that meets your needs and offers durability. Spending a bit more could save you from future headaches. Reflect on what features you truly need. This could lead to a more satisfying purchase decision.

Choosing the right size for a mobile paint booth is crucial. Consider the size of the items you will spray. A larger booth allows for bigger vehicles and projects. However, a large booth requires more space. Measure your workspace carefully. Don't forget to account for ventilation needs. Proper airflow is vital for paint application.

Think about mobility as well. A booth that is too large may be cumbersome to move. On the other hand, a smaller booth can be portable but might limit your options. Assess your typical project sizes. If you often paint cars, you may need a spacious booth. If just small parts are your focus, a compact option could suffice.

Reflect on your workspace layout. Ensure that you have enough room not just for the booth, but for movement around it. Clutter can hinder the painting process. Take time to imagine the workflow. Where will you position the lights? Will you need additional equipment nearby? These details matter in optimizing your painting experience.

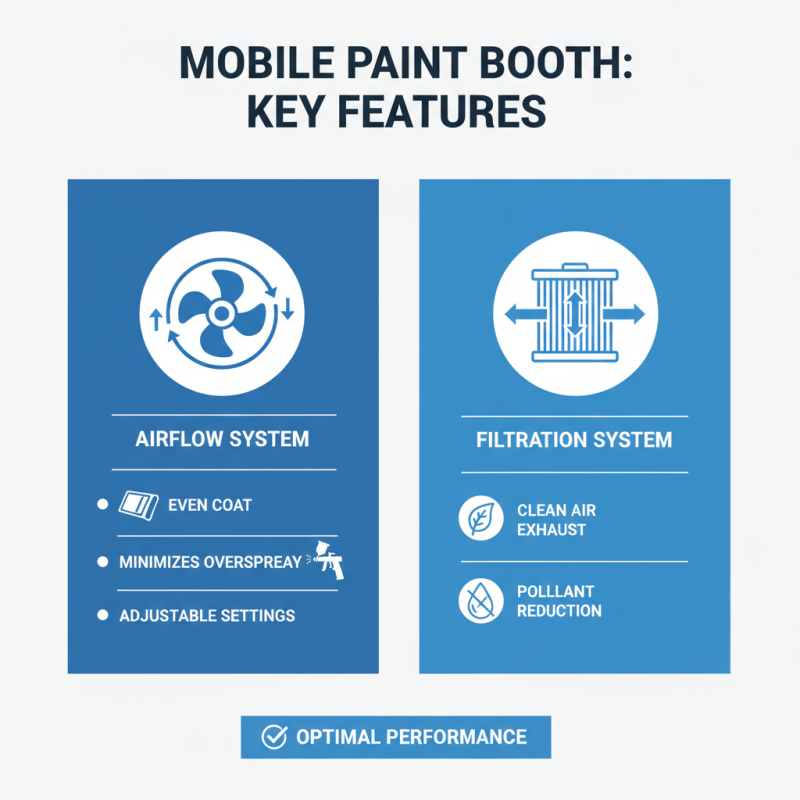

When selecting a mobile paint booth, consider airflow and filtration systems as they significantly impact spray performance. Optimal airflow helps achieve an even coat while minimizing overspray. Look for booths with adjustable airflow settings for better control.

Tips: Check the booth's CFM (cubic feet per minute) rating. Higher CFM usually indicates better airflow. Ensure it meets your specific project requirements. Don't ignore the booth's size. A cramped space may affect airflow patterns and finish quality.

Filtration systems are crucial for maintaining a clean environment. They capture overspray particles, allowing for a better finish. Some booths use multi-stage filters to enhance purification. Evaluate the filter replacement frequency. Frequent changes can increase maintenance costs, so balance efficiency with expense.

Tips: Inspect the filter quality. Look for HEPA filters or equivalent options. They are ideal for trapping fine particles. Also, ensure that the filtration system can handle your spray material. An inadequate system will lead to poor results. Always consider how the airflow aligns with your spraying technique. This might require some trial and error.

Choosing the right mobile paint booth involves a careful balance between cost and essential features. Many buyers are tempted to opt for the cheapest option, but this can lead to compromises in quality and efficiency. Industry reports indicate that nearly 45% of DIY painters have faced issues with inadequate ventilation or poor air filtration, which can impact results and safety.

Ventilation is crucial. A booth with subpar airflow can lead to paint defects. Premium booths often include advanced filtration systems that may cost more upfront. Yet, this investment can result in better finishes and less time spent on corrections. Data suggests that better airflow can reduce over-spray waste by up to 25%, making it a cost-effective choice over time.

Furthermore, consider portability features. Some options have wheels and built-in support frames, while others may lack these vital components. A study indicates that 60% of mobile booth users regret not prioritizing ease of transport. This insight reflects how crucial it is to assess your workspace and transport needs before purchasing. Balancing your budget with these essential capabilities is key to making a wise investment.

| Booth Type | Cost (USD) | Size (ft) | Airflow (CFM) | Portable | Ease of Setup |

|---|---|---|---|---|---|

| Tent Booth | $1,500 | 10 x 10 | 600 | Yes | Easy |

| Inflatable Booth | $2,000 | 12 x 12 | 800 | Yes | Very Easy |

| Rigid Booth | $5,000 | 14 x 21 | 1200 | No | Moderate |

| Cargo Trailer Booth | $6,500 | 20 x 10 | 1500 | Yes | Difficult |

| Pop-Up Booth | $3,000 | 10 x 20 | 700 | Yes | Easy |

When selecting a mobile paint booth, compliance and safety standards are crucial. The National Fire Protection Association (NFPA) has published guidelines that indicate proper ventilation is necessary to reduce fire risks. A well-ventilated booth should have an air exchange system rated at least 20 air changes per hour. This helps mitigate flammable vapor accumulation. The absence of such features can jeopardize safety, leading to potential accidents.

OSHA regulations also play a significant role in booth design. Employers must ensure that their booths comply with specific ventilation requirements to protect workers from harmful fumes. According to a report, improper ventilation can expose workers to levels of VOCs exceeding OSHA limits. Moreover, adequate personal protective equipment (PPE) should always be mandated. While many booths come with built-in systems, they may not always meet local codes.

In evaluating options, consider energy efficiency alongside safety. Some booths may excel in compliance but lag in energy usage. Recent studies suggest that energy-efficient booths can reduce operational costs by up to 30%. Balancing these factors can feel overwhelming, but it’s essential to prioritize safety without compromising efficiency.

Hein Minnie

Cell nr: +27 (0) 82 564 6501

Email: sale@thecirclemachine.com

Hein Minnie Jnr

Cell nr: +27 (0) 84 284 7234

Email: sale@thecirclemachine.com

Address:

10 Apsey Street,

Heidelberg,

Gauteng,

1441

Bendet Engineering Services (PTY) LTD was established in 1987. Our team of engineers and draughtsman are ready to deliver a complete turnkey solution, from the design phase to commissioning. A dedicated team that consists of electrical, mechanical and industrial engineers, we are able to offer a comprehensive service to our clients.